General Wheel, Tire, Suspension & Running Gear Maintenance

Our running gear has been designed and selected to provide low maintenance trouble free use. Service intervals MUST be followed as this is an off and on road trailer vehicle. It is the sole responsibility of the owner to complete maintenance

Maintenance Schedule REFERENCE LINK

Wheel Nuts

- it is critical to check torque at required intervals above

- wheels often have a settling in period where lug nuts require tightening

- trailers tend to experience higher wheel loads than vehicles

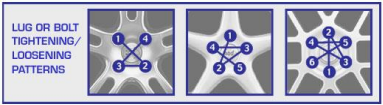

- check torque in the following pattern:

Brakes

- Follow the above and manufacturer recommended inspection and maintenance intervals. Check tightness of brake mounting bolts, replace pads/shoes if necessary. Ensure brake controller performance is adequate and gain/settings are adjusted as per the controller manufacturer spec to have the best electric trailer brake performance as necessary

- Brake liners, solenoids, and assemblies are a service/wear item and are not covered under warranty

Suspension and Shock (Evolution Series) Absorber Mounting Bolts and Inspection for Leaks (Evolution Series)

- All bolts should be tightened as per recommended torque specs

Hinge/Pivot Bolts

- Where Zerk fittings - using grease gun, pump grease through nipples (Zerk) until it comes out around the bushings

- No Zerk fittings - utilize WD40 as required but with maintenance free bushings it is critical to keep area clean and not over grease

Inspection of Suspension Bushings

- Any parts showing premature or normal signs of wear should be replaced.

Wheel Alignment

- Depending on your suspension model you can review wheel alignments as follows:

Wheel Bearings

- Follow the owners manual and above maintenance guide always

- Wheel bearing replacement - bearings must be dismantled and inspected. Replace bearing as necessary

![OGT logo-2.png]](https://support.offgridtrailers.com/hs-fs/hubfs/OGT%20logo-2.png?height=50&name=OGT%20logo-2.png)