Timbren Suspension Maintenance, Alignment and Operation - Including brake and hub

**Scroll to the bottom of this article for main and sub component part numbers and links.

Bolt checks

As outlined in the Timbren manual, the Timbren suspension system periodically requires maintenance. Within the first week of use, torque of all bolts must be checked. Subsequent to this, after 4 months, the same check, and then yearly. It's recommended that these fasteners be checked after EVERY off road excursion where severe loading is encountered.

- See below for a table copied directly from the Timbren manual:

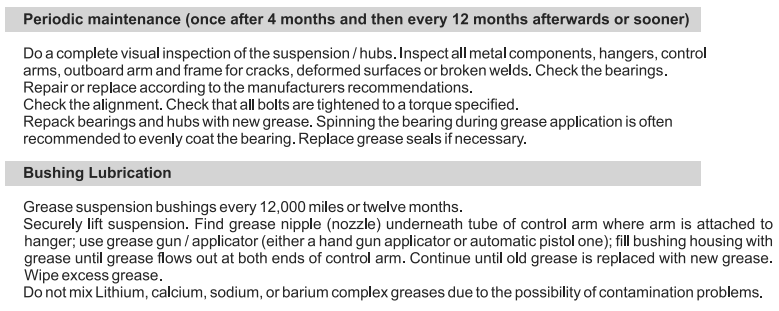

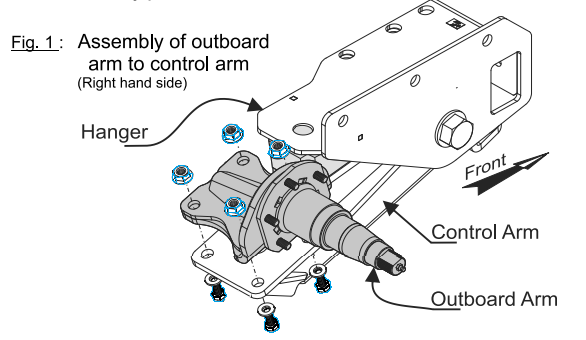

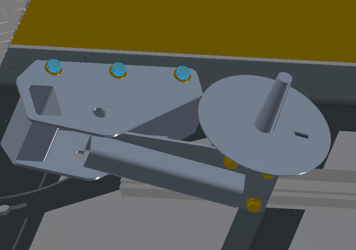

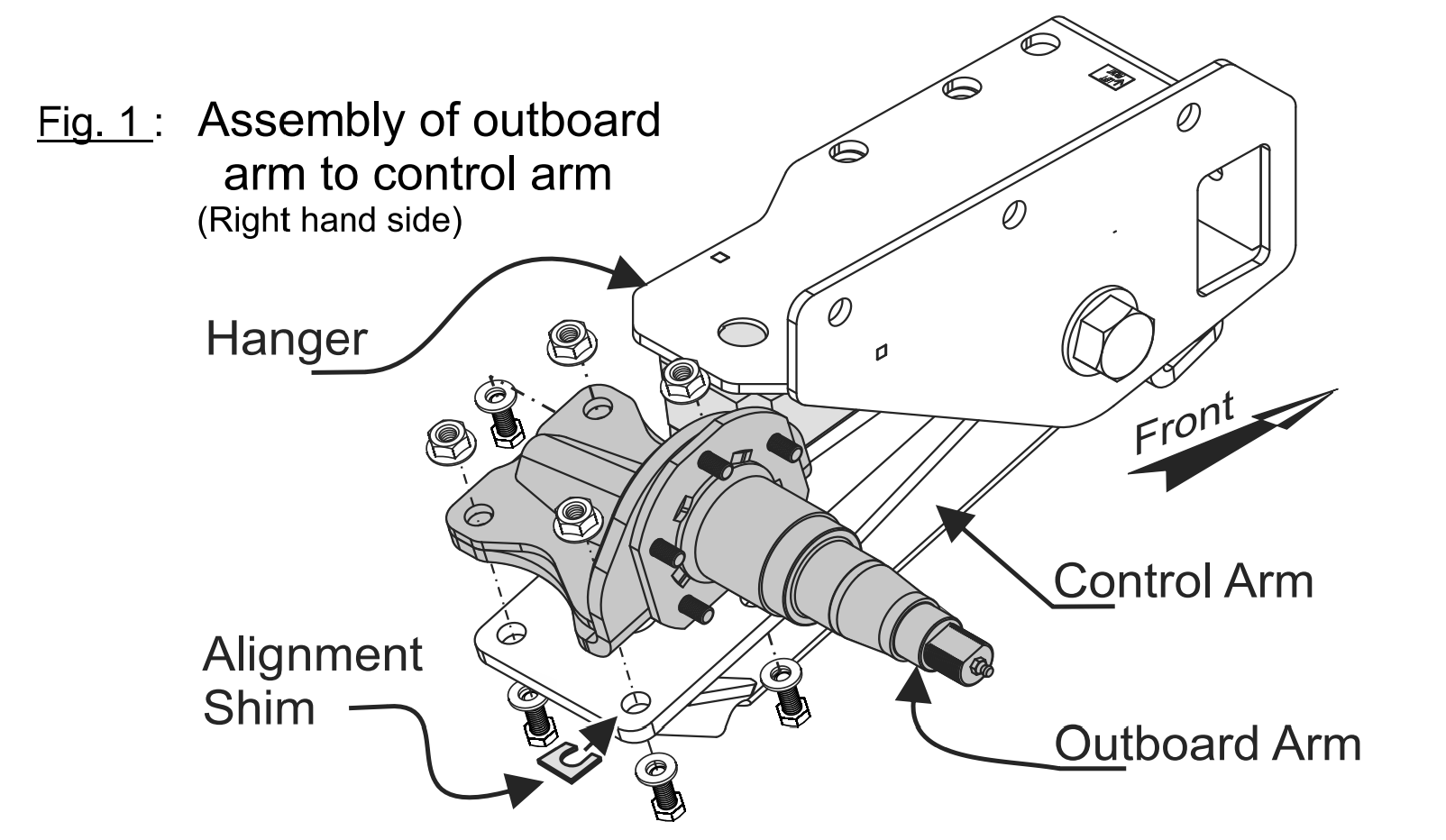

The control arm outboard bolts are highlighted in blue, above. The torque specification for these bolts is 155-165 ft-lbs (210-224 Nm)

There are 6 bolts in total retaining the Timbren suspension mount to the trailer frame. Each of these should be checked for torque to 165-175 ft-lbs (224-237 Nm.)

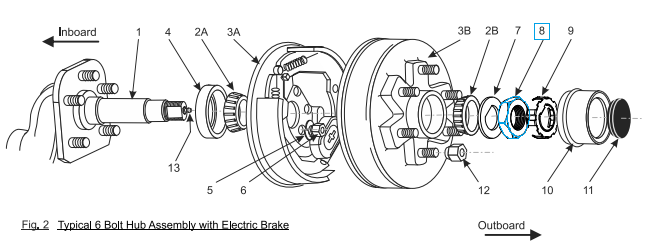

The above item 8, the axle nut, can be used to take slack out of the hub bearing assembly. Just the same as with the mounting bolts, the torque of this bolt should be checked if there is any lateral movement in the wheel assembly when the tire/wheel is raised from the ground.

Free spinning of the assembly must also be confirmed.

- Timbren Installation Guide HERE

- Drum Brake installation and service guide - see below

Finally, the main pivot bolt for each suspension, highlighted in blue below, should be checked for torque at 430-470 ft-lbs (583-638 Nm.) This is best performed at a service shop that has a torque multiplier or a controlled torque wrench - truck and trailer service facilities.

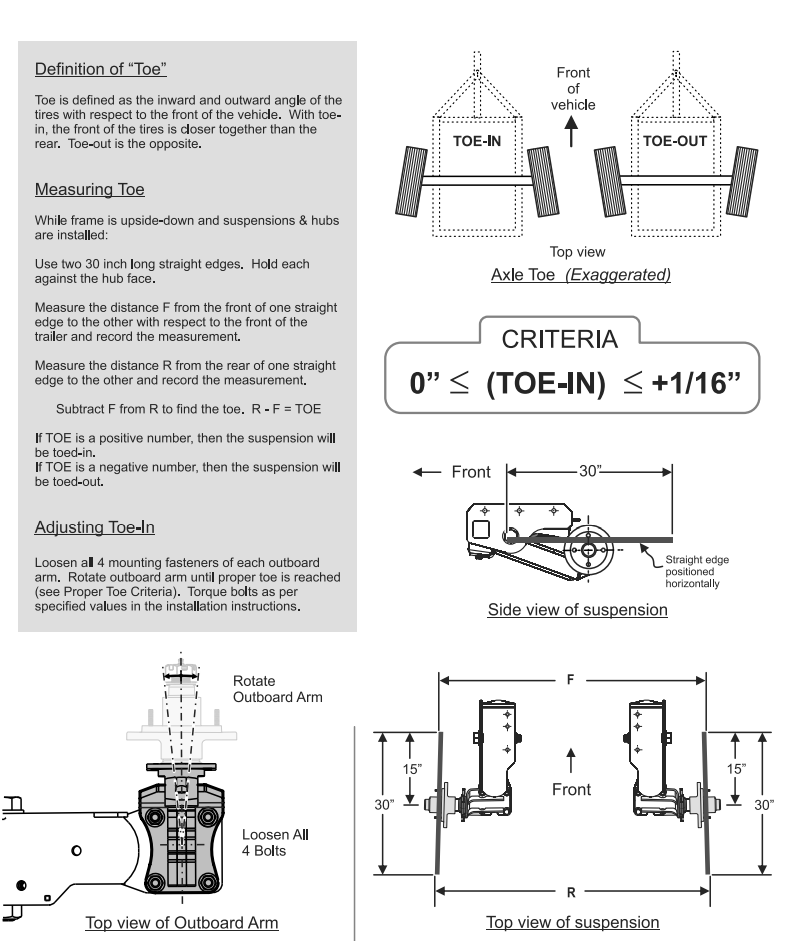

Alignment

Important!! Before beginning an alignment, raise each wheel individually and confirm that the bushings on which the suspension pivots, at the front of each control arm, are intact and no free play is present. If the bushings have failed, they will need to be replaced prior to correcting the alignment.

*IF you need parts; if any piece of the Timbren suspension has failed such as bushings/hubs/bearings during the OGT warranty period, Timbren administers their own warranty of 3 years on these components.

You can contact Timbren at:

or call 1-800-263-3113.

Knowing good information about bolt locations and torques, we can go on to the information on alignment.

The alignment specifications are:

- Toe in is set between 0" and 1/16" TOE IN - see diagram below.

- Camber is set to 0 degrees to +0.5 Degrees.

Take particular notice that the two (F, R,) toe measurements shown in the diagram below are taken at a diametrical distance of 30 inches. On each side, it is helpful to use a piece of angle or other scrap material, cut to length and drilled such that it can be installed on a pair of the lug studs. It is practical to set one hub parallel to the frame, tighten that spindle down to the control arm, and then adjust the other spindle to set toe with respect to the fixed side. Ensure the trailer does not "dog track," and adjust if required.

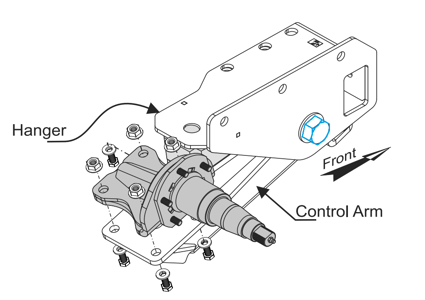

Shimming for Camber

The diagram above includes placement for an alignment shim where the shim would add negative camber to the suspension system. A 5/8" ID Grade 8 washer can also be used in this location (check your bolts first to ensure they are equal to or less than 5/8" OD, adjust fastener choice to suit.)

This document is a guideline and is meant to be used in concert with the Timbren instructions.

If you have any questions about the alignment process, please contact OGT warranty at warranty@offgridtrailers.com or call the switchboard at (800) 786-3221 and ask to speak with technical support.

**IF you need parts, if any piece of the Timbren suspension has failed such as bushings/hubs/bearings during the warranty period, Timbren administers their own warranty of 3 years on these components. You can contact Timbren at:

or call 1-800-263-3113.

Part Numbers/Part Reference & Common Work Instructions for Timbren 3500 HD only

Suspension kit

Timbren Part: ASR35HDS02 - 3500 lb HD Axle-Less Trailer Suspension w/ 4” Lift & Long Spindles

For sub component ordering and part numbers, including main pivot bushings should they show wear, please contact Timbren at sales@timbren.com

Brake and Hub:

Timbren Part: 500931RH/LH (Left and Right handed.)

Generic service kit from Dexter, and part number listing:

https://www.dexteraxle.com/product/2644/114/hub-drum-kit

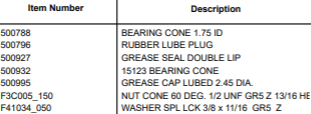

From above, here's a table of sub component part numbers

NOTE: The diameter for the grease seal is NOT 2.125" it is 2.25". The table below is outdated for that part. GS-2250DL is the universal part number.

- Dexter axles used with the Timbren suspension:

- Timbren Part numbers:

Reference Guides:

How to manually repack bearings on a trailer

Proper Bearing Lubrication Type

Note that tire wear issues are NOT covered by the OGT manufacturers warranty and it is the responsibility of the trailer owner to verify camber and toe measurements as well as all torque specs outlined in the owners manual and above.

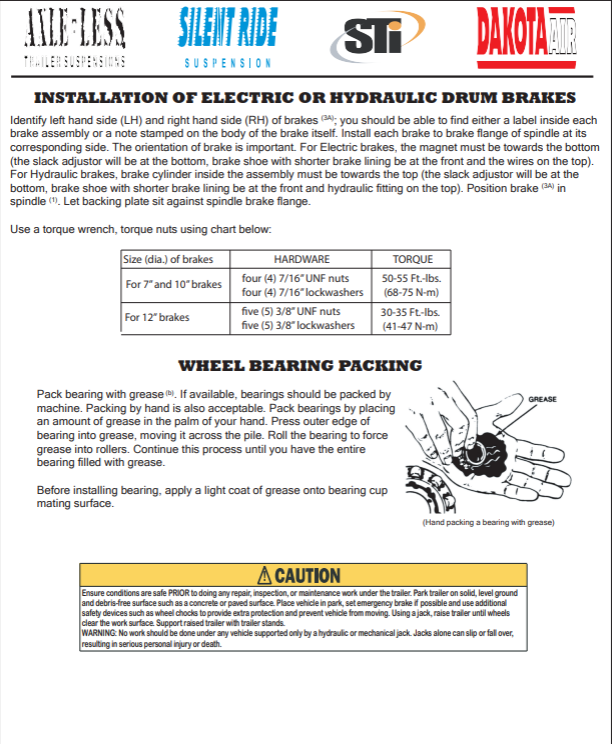

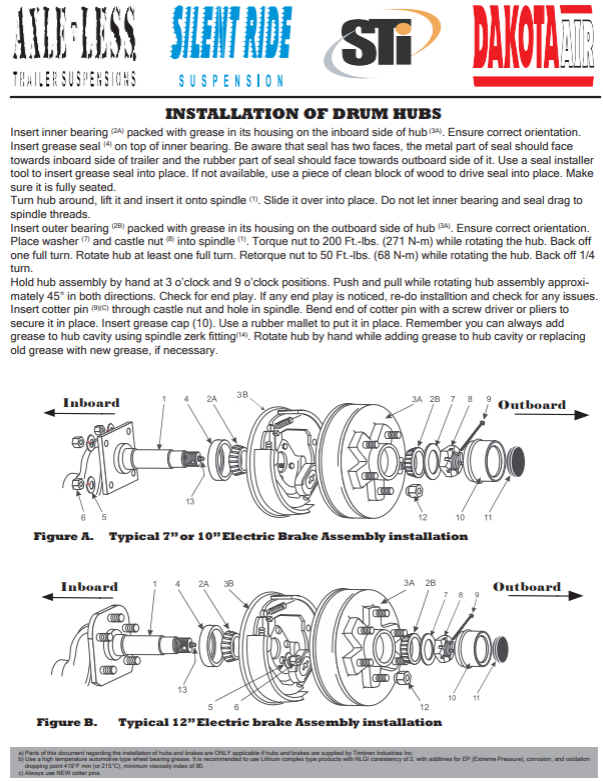

Installation of Electric Drum Brakes & Bearing Maintenance

![OGT logo-2.png]](https://support.offgridtrailers.com/hs-fs/hubfs/OGT%20logo-2.png?height=50&name=OGT%20logo-2.png)