Trailer Lubrication

Here's an article on how best to service the lubricants used on your Off Grid Trailer.

Grease Type

We are currently using Propel Calcium Sulphonate grease for the Timbren suspension pivots, wheel bearings, and CU Off Road pivots. It features the following qualities:

- High performance, extreme pressure grease with resistance to corrosive saltwater environments

- Crafted using calcium sulfonate thickeners that provide outstanding film strength to protect moving surfaces

- Ideal for automotive use as well as extreme pressure applications in construction, mining, agricultural, logging, hauling, and other industries where a shear-stable, high load carrying, corrosion resistant grease is required

- Highly water resistant

- Usable in temperatures from -29°C to 260°C (-20°F to 500°F)

- Protection from rust and corrosion

- Does not drip out under running conditions

- Suitable for high speed bearings and centralized lubrication systems

- Be sure to follow OEM grease grade and compatibility on all recommendations

- Principal Uses Properties – Multi-service includes rolling contact bearings, plain bearings, and others

- Water Resistance Properties – Functional effect ranges (i.e. good to excellent) may cover multiple greases as listed

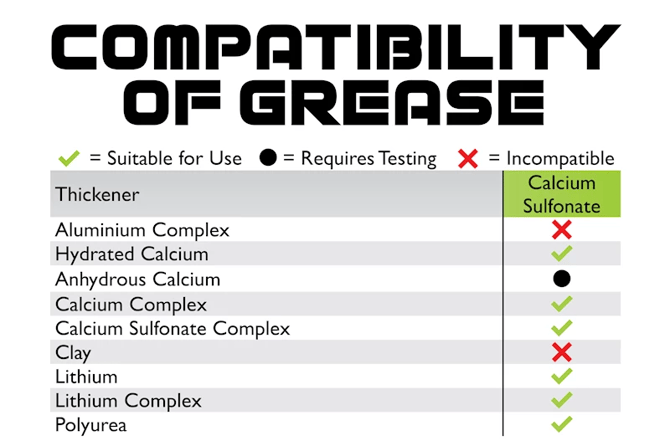

- Suitable for Use: Hydrated Calcium, Calcium Complex, Calcium Sulfonate Complex, Lithium, Lithium Complex, and Polyurea

- Requires Testing: Anhydrous Calcium

- Incompatible: Aluminium Complex and Clay

The grease above is the only lube applied at the factory during assembly.

Pre-applied lubricants

Some parts we buy from our 3rd party vendors come pre-lubricated. The XO jacks have a wax protectant on them - if you wish to replenish this, corrosion inhibiting cavity wax works well.

Lubrication of doors, latches, and hinges

Suspension and wheel bearings

The Timbren suspension is lubricated via a grease zerk underneath the main pivot point that attaches the control arm to the suspension hanger. Every 12,000 miles or 12 months, fill the suspension pivot housing with grease until fresh grease comes out either side of the control arm.

At the same interval, lubricate the Timbren wheel bearings via the zerk located underneath the center cap - install grease until it uniformly comes out of the bearings.

The Evolution Suspension pivot bushings are maintenance free. Only the wheel bearings require inspection and repacking during regular maintenance intervals. Refer to your owner's manual PDF. There is no grease zerk in this system - the castle nut must be removed and the brake hub taken off so that the inner and outer bearings can be removed, cleaned, inspected, repacked, and replaced. If you have any concerns about performing this service yourself, please consult with the OGT technical services department at warranty@offgridtrailers.com, or seek out a good local trailer or automotive service shop.

![OGT logo-2.png]](https://support.offgridtrailers.com/hs-fs/hubfs/OGT%20logo-2.png?height=50&name=OGT%20logo-2.png)