My Evolution Series suspension squeaks: how can I confirm the cause and troubleshoot?

This reference guide is dedicated to troubleshooting audible/cosmetic squeaks in the suspension system (Heims joints, etc)

Materials:

- WD 40 spray lubricant

- Multi use socket set (minimum 3/8 drivers to accommodate torque)

Common Reasons:

- Your evolution series suspension, outside of inspection intervals references in our maintenance guide, is near maintenance free

- Common reasons for audible noise are caused by the user greasing, lubricating, or utilizing unapproved methods to grease the suspension

- OGT recommends annual cleaning and WD40 application to the suspension bushings

- There are no Zirk (grease nipple style) fittings on the suspension indicating near maintenance free

- Common reasons for audible noise are caused by the user greasing, lubricating, or utilizing unapproved methods to grease the suspension

Steps:

- Disconnect trailer from vehicle.

- Go to side of trailer and push/rock the trailer back and forth / up and down to recreate the squeak noise.

- If trailer makes the audible noise, see if you can determine which side of the trailer it is coming from.

- If you cannot recreate the noise (possible brake pad noise)

- reconnect the trailer to the vehicle and with a second individual move the trailer forward at backwards no more than 5mph to determine noise/location (drivers/passenger)

- Address the contact points one at a time with the WD40 so we can determine the source of the noise.

-

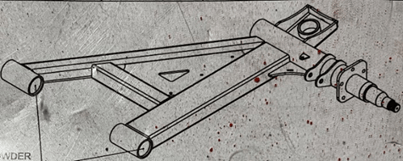

- There are 6 points on the trailer to troubleshoot - See below for reference

-

-

- Drivers Side

- Control arm mount points (crossmember x 2)

- Shock mount point to the control arm

- Passenger Side

- Control arm mount points (crossmember x 2)

- Shock mount point to the control arm

- Drivers Side

-

- Spray one contact point and then try to recreate the noise. At the point you eliminate the noise you stop and contact OGT with the location.

-

- Control arm mount locations shown in image with arrow lines. Working from the outboard to inward.

- Spray outside of bushing at the bolt then check for noise.

- Move progressively to the inside of the bushing bolt to lubricate and try to make the noise.

- Move to the other bushing on the arm and do the same.

- If the control arm bushings are not the source of the noise, you will move to the shock mounts.

- There is only a top and bottom to each shock. Start with the top mount and then move to the lower mount.

-

- Contact OGT at warranty@offgridtrailers.com

Reference Guides:

How to manually repack bearings on a trailer

Proper Bearing Lubrication Type

![OGT logo-2.png]](https://support.offgridtrailers.com/hs-fs/hubfs/OGT%20logo-2.png?height=50&name=OGT%20logo-2.png)